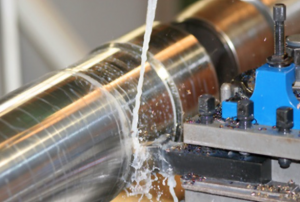

Whoever you are experienced formulators or just marketers of metalworking fluids, Horlt Chemical can always find the tailored solutions to meet your specific requirements either additives or fully formulated fluids.

1. Performance Additives

Horlt Chemical provide the metalworking fluids formulator a genuine choice of additives. Not just traditional amides and esters, but innovations lead additives with performance. Our range includes:

- Corrosion Inhibitors (Boron Containing, Boron Free)

- Multi Metal Passivators (Cu, Al, Mg, Zn)

- Amine Carbamates

- Rust Preventive Additives

- Multi Functional Amides

- Primary Emulsifiers (PIBSAs, Sodium Sulfonates, Ethoxylated Glycerol Fatty Acids, Sulfated Oils)

- Secondary Emulsifiers (Ether Carboxylates, Carboxylic Acids, Distilled Tall Oil Fatty Acids)

- Coupling Agents

- Lubricity Additives (Complex Esters, Polymeric Esters, Self-emulsifying Esters, PAG Esters)

- Phosphorous based Antiwear Additives

- Extreme Pressure Additives (Chlorine, Phosphorous, Sulfur)

- Antifoams & Defoamers

- Biocides & Fungicides

- Demist Additives & Tackiness Agents

- Antioxidants

- Fine Separation Agents

- Chelating Agents

Our experience of finished formulation requirements enables Horlt Chemical to provide a range of additives offering unique solutions to the physical and legislative issues facing the lubricants industry.

2. Packages, Intermediates & Concentrates:

Horlt Chemical offer a choice of ‘off the shelf’ products for the manufacture of oil based (naphthenic or paraffinic), or fully synthetic metalworking fluids, or packages developed to a customer’s specification.

Horlt Chemical is one of the market leaders for the development of packages for use in the production of metalworking fluids. Generally a metalworking coolant can be easily made by blending an emulsifier package with its base oil. Depending on the end use, water, EP/AW support, biocide and yellow metal inhibitor can be added.

Using packages facilitates production and formulation of metalworking coolants for a variety of reasons:

- Simple storage of ready-to-use packages

- Short production cycles

- No development work

- State-of-the-art technology

- Conformity with current health and safety standards

- Proven formulations

- Lower fixed costs

Horlt Chemical offers a wide range of packages for metalworking coolants:

- Conventional metalworking fluids (milky fluids)

- for hard and soft waters

- with different treat rates and corrosion protection properties

- semi-synthetic fluids based on sulfonates but boron free

- semi-synthetic (long life) fluids based on boron amines but sulfonate free

- low foaming formulations

- packages for use with aluminium

- Amine-, boron- and preservation agent free semi-synthetic packages

- Amine-, boron- and mineral oil free semi-synthetic packages

- Packages for fully synthetic fluids

- Tailor made packages for specialty process emulsions

In addition any type of special package can be made to suit customer requirements on an individual basis, covered, if necessary, by confidentiality agreements. All products are free of nitrites and generally free of DEA, which is only used at the express wish of the customer.

3. Fully Formulated Finished Fluids

Horlt Chemical recognise it may be unpractical or undesirable for customers to blend their own metalworking fluids. Thus Horlt Chemical offer a comprehensive range of neat and water-mix metal cutting and forming fluids such as:

- Boron-free Technology

- Very high performance EP water-mix cutting fluids

- Aluminium specific aerospace fluids

- True chlorine-free alternatives both oil containing and fully synthetic

- Water-mix/wash neat oil replacement pressing and forming fluids

- Chlorine and sulphur-free neat pressing and forming fluids

Whilst standard ‘me too’ type products are available, often these products are developed in conjunction with the customer where a unique requirement presents itself. All fluids are developed and tested in line with strict evaluation and quality standards taking consideration of process and environmental limitations.

Where desired, exclusivity to developed products can be assured, given agreed annual volume predictions.

Horlt Chemical are always keen to embrace new technologies in the development of market leading products to enable you to provide your customer innovation and performance.

The formula for success is: the customer’s strong international or regional brand plus Horlt Chemical’s innovative formulas and services.